VACUUM PLANTS FOR COMPOSITE INDUSTRY

MIL’S has put all its know-how to work to develop and to improve a range of units and accessories to meet the specific needs of the composite industry. We offer a variety of vacuum units to tackle processes such as infusion, vacuum moulding and Light R.T.M.

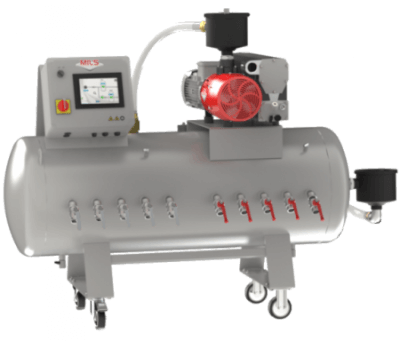

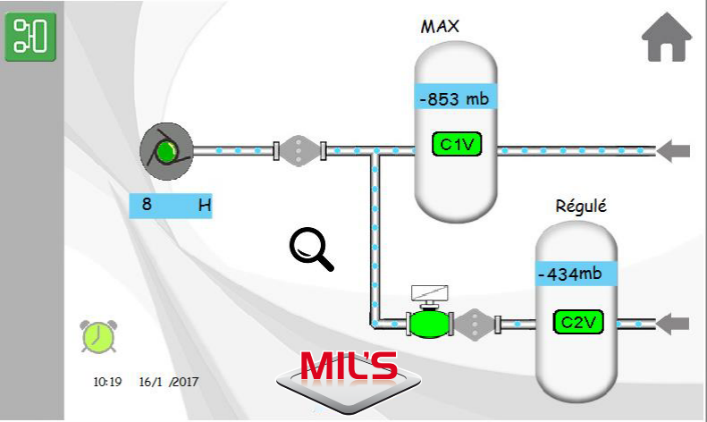

Regardless of whether you chose a mobile or fixed solution, our products help you to produce the most complex parts for industries like the automotive, aeronautics or water-sports ones. The Millenium PLC with its additional touch screen now permits a intuitive control of the Compositvac or Indusvac plant with the recording of performance, events, alarms and the maintenance management.

The Light Resin Transfer Moulding (RTM) process consists in producing a composite part using a closed mould. The glass fiber is positioned in the mould. The maximum vacuum ensures that the mould closed perfectly. The resin is then injected into the periphery using a machine at low pressure and drawn under a controlled vacuum applied from the center of the mould. Our Compositvac units have been designed to satisfy both vacuum requirements. Their two vacuum levels can be controlled by the operator to provide accurate polymerization times and speeds for the different resins. The active carbon filter improves shop working conditions by trapping COV emissions.

This solution can also be implemented using a centralized system. In this case, alongside an Indusvac unit installed to supply maximum vacuum to the entire workshop, each workstation is equipped with its own stand-alone 70l receiver controlled by an high-precision vacuum switch.

This configuration enables a workstation to produce parts under a given vacuum level with no affect on the other workstations.

Vacuum moulding or vacuum forming is probably one of the most common types of thermoforming. A sheet of material is heated to soften it until it’s malleable and then put into shape onto a forming core or tool by vacuum. Vacuum forming machines ranging from small tabletop models to industrial machines, MIL’S offers various configurations : pumps with controllers, Indusvac.

Vacuum moulding or vacuum forming is probably one of the most common types of thermoforming. A sheet of material is heated to soften it until it’s malleable and then put into shape onto a forming core or tool by vacuum. Vacuum forming machines ranging from small tabletop models to industrial machines, MIL’S offers various configurations : pumps with controllers, Indusvac.

Evisa pumps and Indusvac plants are used in High tech industry too. Parts used on racing cars, aircrafts or racing skis are made of carbon fibre. These parts are treated in an autoclave where the vacuum assists the compacting of successive layers. The heat gradually frees the prepreg and the vacuum ensures its uniform distribution. The pump(s) can be installed at the foot of the autoclave or can be feeding a centralized network. In this configuration the Indusvac is provided with 2 or more pumps because given the cost of the manufactured parts, the presence of a stand-by pump is essential.

Vacuum infusion is another process using two vacuum levels: the maximal level to apply the plastic film to the parts to be bonded and a second level to draw the resin from the pails and make it flow uniformly over the entire surface to be bonded.